Crouvezier Développement can offer you a wide range of finishing options to give your fabric any specific function you may need; a technical performance, a different appearance or touch.

Mechanical finishing describes the processes using mechanical means in order to improve the fabric to its ultimate use. It can alter the alter fabric lustre, smoothness, softness, residual shrinkage and hand.

What we offer at Crouvezier Devéloppement:

-Emerising : the fabric is passed over one or more rotating emery-covered rollers to produce a “peach-skin” finish; giving a softer handle to the fabric similar to a natural peach-skin ;

- Calendering : the fabric is compressed by passing it between two or more rollers under controlled conditions of time, temperature and pressure in order to reduce fabric thickness, increase fabric lustre, increase fabric cover, smooth silky surface feel and reduce air porosity ;

- Raising : the surface of the fabric is scraped with metal spikes so as to bring out the fibres and create a fluffy and dense raised surface ;

- Sanforising (pre-shrinkage treatment): it improves the dimensional stability of the fabric, thus guaranteeing limited shrinkage during washing. It also gives a soft handle to the fabric ;

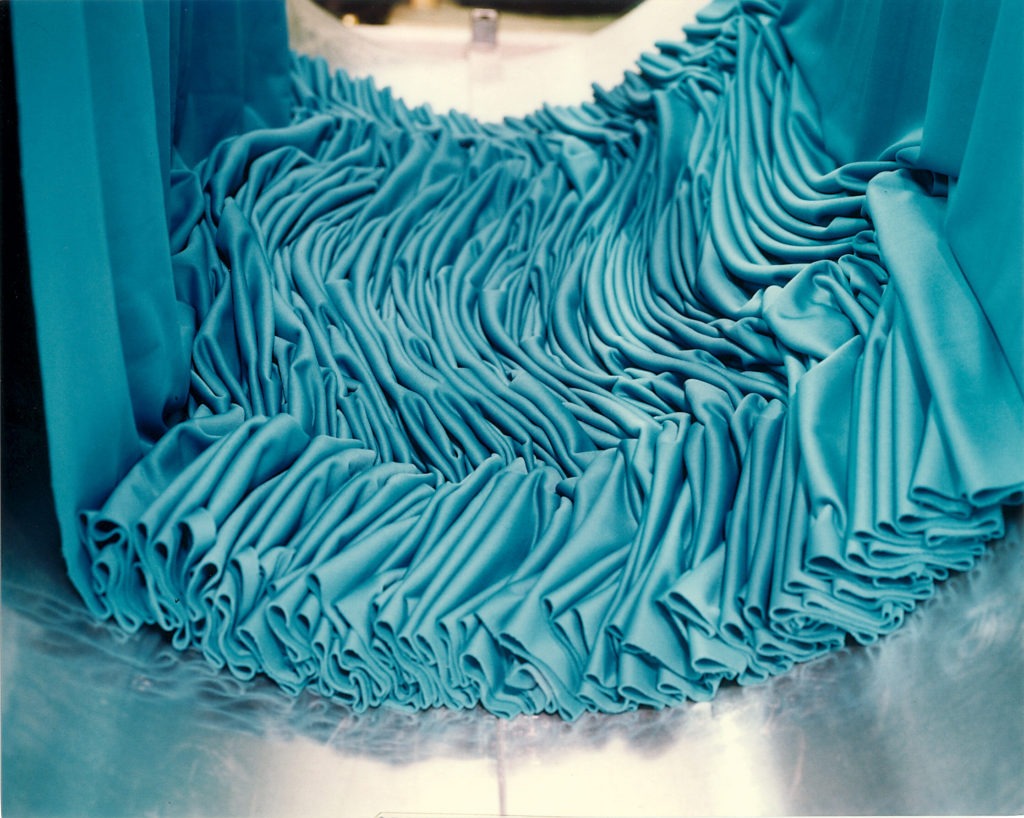

- Tumbling it softens the fabric and gives it more volume by scattering it several times on a façade at a high speed and at a certain temperature.

Chemical finishing involves the addition of chemicals to textiles to achieve the desired result. Generally, the appearance of the fabric is unchanged with chemical finishing.

What we offer at Crouvezier Développement:

- Softening finishes : brings agreeable soft hand (supple, pliant, sleek, fluffy), smoothness, more flexibility and better drape and pliability ; and hand building finishes: brings firmness to fabric hand ;

- Easy-care and durable press finishes : it allows to minimises the wrinkling effect of cotton after washing and therefore minimises the need of care (easy-to-iron/no-iron, wash and wear, crease-resistant, durable/permanent press, wrinkle resistant/wrinkle free) ;

- Repellent finishes: treated fabric repels water, oil and dry dirt. The treatment prevents fluids from wetting the fabric but still let’s air through (good wear comfort compared to waterproofing finishes) ;

- Waterproofing finishes makes the textile waterproof and airtight. The fabric is impregnated with a resin-based hydrophobic solution that seals its holes ;

-Soil-release finishes facilitates the removal of soils during laundering ;

-Flame retardant finishes : delays the start of ignition of the textile exposed to fire and avoids or delays its propagation. Examples of use: Firefighters and emergency personnel protection, floor coverings, upholstery and drapery (particularly in public buildings), transportation, ...

-Non-slip finishes : increases the adhesion between fibres and yarns ; antistatic finishes ; anti-pilling finishes ; antimicrobial, insect and mite protection finishes ; colour fastness improvement finishes : improves washing, water, perspiration and ironing fastness ;

- Mercerisation : this consists of impregnating the cotton fabric with caustic soda, thus swelling the fibre. This improves the shine and tear resistance of the fabric and also reduces fabric shrinkage ;

-Optical brightening finishes addition of fluorescent products (brighteners) intended to make the white even whiter ;

- Other finishes such as microencapsulation (with PCMs - Phase Change Material -, cosmetics, ...), anti-odour, fragrance finishes and so on.

Your textile can be chemically finished by pad-application, coating and laminating:

- Pad-application : the fabric is immersed in a bath with the chemical finishing and pressed (or not) between two rollers. This technique allows a deep impregnation of the finish ;

-Coating : the fabric to be coated runs under a knife over roll coater with a coating paste which is deposited on the surface of the textile (single-sided treatment) ;

- Lamination : it allows to join several textiles layers with a chemical acting as the adhesive. Example of application: in clothing, a soft touch is sought for the layer in direct contact with the skin and a weather-proof layer for the outer layer.

COPYRIGHT © 2020 Crouvezier Développement / Site créé par Im’plante ta marque